In the fast-paced world of inventory management, where precision and efficiency are paramount, adopting the 5S methodology becomes more than just a practice—it’s a philosophy.

Join us on a journey as we explore the impact of 5S principles on transforming workspaces into hubs of productivity and excellence.

The Essence of 5S

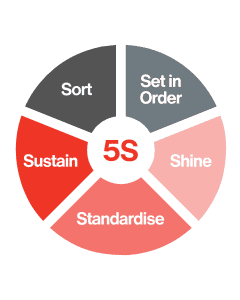

Let’s begin by exploring the foundational principles of the 5S methodology—Sort, Set in Order, Shine, Standardise, and Sustain.

The 5S methodology aims to revolutionise your workspace, fostering a culture of efficiency and continuous improvement.

This exploration will guide you in creating an organised, streamlined workspace that goes beyond mere physical order—setting the stage for increased productivity, reduced frustration, and operational excellence.

Sorting for Success

Embark on this transformative journey with the first “S” in the 5S methodology—Sort.

The art of sorting extends beyond decluttering; it’s a strategic process of prioritising, organising, and optimising.

By systematically evaluating and categorising items, you not only create a physically organised environment but also lay the foundation for streamlined processes. This careful curation ensures that only the essential items remain, minimising waste and unnecessary complications.

The art of sorting becomes a stimulus for reducing frustration, saving time, and ultimately increasing profitability. It’s the first step towards creating a workspace that not only looks organised but functions seamlessly, contributing to the overall success and efficiency of your business operations.

Setting in Order – A Symphony of Arrangement

Transitioning seamlessly from the art of sorting, we delve into the second “S” in the 5S methodology—Set in Order. Beyond the initial decluttering, the systematic arrangement takes centre stage, unveiling the transformative power of an organised workspace.

A well-organised environment is more than aesthetically pleasing; it’s a strategic approach to minimising waste, reducing errors, and elevating overall workflow efficiency. Every item finds its designated place, contributing to a seamless flow of operations.

The systematic order not only enhances accessibility but also streamlines processes, ensuring that tools, materials, and information are readily available when needed.

As each component aligns purposefully, the workspace becomes a haven of efficiency, reducing frustration, saving time, and laying the groundwork for increased profitability.

The second “S,” Set in Order, becomes a key step in the journey toward creating a workspace that not only looks organised but functions with unparalleled precision.

Shining for Perfection

As we continue on the journey through the 5S methodology, we arrive at the third pivotal step – Shine.

Beyond the systematic arrangement of Set in Order, Shine introduces a new dimension, focusing on cleanliness and maintenance.

Picture a workspace that not only looks organised but gleams with cleanliness. It’s a commitment to excellence. A shining workspace is not just a reflection of pride but a vital part of operational efficiency.

Regular cleaning and maintenance not only reduces downtime caused by equipment malfunctions but also contributes to the longevity of tools and machinery.

An environment that shines with cleanliness fosters a culture of excellence, setting the stage for heightened productivity and a smoother workflow.

The third “S,” Shine, transforms the workspace into a beacon of efficiency, where every detail is tended to, ensuring not just order but a commitment to operational excellence.

Standardising Practices

Having journeyed through the 5S methodology, we now arrive at the fourth crucial step – Standardise.

After achieving a shining workspace through cleanliness and maintenance, the focus shifts to establishing uniform processes and practices.

Standardisation is the backbone that ensures the sustained efficiency of the workplace.

Imagine every task, every process follows a set standard – a defined and optimised way of operating. This not only minimises errors but also fosters a culture of continuous improvement.

Standardised procedures create a reliable and predictable environment where every team member knows what to expect, promoting a streamlined workflow.

The fourth “S,” Standardise, is the architect of sustainable efficiency, providing the foundation for a workplace that operates seamlessly, reducing variability and enhancing overall productivity.

Sustaining Excellence

As we conclude our exploration of the 5S methodology, we arrive at the fifth and final “S” – Sustainability.

Having sorted, set in order, shined, and standardised, the journey peaks in the pursuit of sustaining the gains achieved.

Sustainability is not just about maintaining a clean and organised workspace; it’s about fostering a mindset of continuous improvement. It involves instilling practices that ensure the longevity of the streamlined processes and efficient workflows established through the 5S methodology.

Sustainability encourages a workplace culture where every team member actively contributes to preserving the optimised environment.

By embracing the fifth “S,” you can conserve the benefits of reduced waste, enhanced productivity, and increased profitability. It embeds the principles of 5S into the business’s DNA, creating a foundation for sustained success and continuous excellence.

Real-world Applications

Witness the transformative journey of 5S with The TwinBin, our inventory management solution, where the principles of the renowned 5S methodology seamlessly integrate to revolutionise your business operations.

In our commitment to reducing frustration, saving time, and increasing profitability, our innovative two-bin Kanban system, aligns with the core principles of Sort, Set in Order, Shine, Standardise, and Sustain.

By storing reserve stock above active stock, it ensures a streamlined and organised inventory workflow. As active stock depletes, a simple pull of the slider releases the reserve batch, leaving the upper chamber ready for new stock.

Join us in embracing efficiency and operational excellence, where the synergy of 5S and cutting-edge inventory solutions transforms the way you manage your parts.

The TwinBin System not only saves you time, money, and effort but also puts you in control of your inventory, ensuring a smoother and more efficient process.

Elevating Your Workspace

As we conclude our journey through the 5S methodology, envision a workspace that goes beyond organisation.

Picture an environment where every tool, process, and individual works in harmony, contributing to maximum productivity and efficiency for your business.

Ready to embark on your 5S journey?

Explore the transformative power of The TwinBin. Lets together elevate your workspace to its full potential, creating a foundation for continuous improvement and operational excellence.