In every industry, from aerospace to pharmaceuticals and beyond, the challenge of navigating disorganised workspaces, managing lost parts, and combating dwindling productivity is a constant battle. Yet, within these challenges lies a powerful solution: Kanban systems. Mastering inventory management is the cornerstone of success, and Kanban systems offer a solution to these common struggles.

In this enlightening blog post, we’ll uncover the untapped potential of Kanban systems, revealing how they can not only streamline your workflow but also catapult your operations to new heights of efficiency and success.

Understanding Kanban Systems:

Kanban, a Japanese term meaning “visual card” or “signboard,” is a lean manufacturing method that

originated at Toyota in the 1940s.

It is a visual scheduling system that enables companies to manage inventory levels efficiently, control the flow of materials, and minimise waste.

Kanban systems use visual cues, such as cards or bins, to signal when inventory needs to be replenished, ensuring a smooth and continuous workflow.

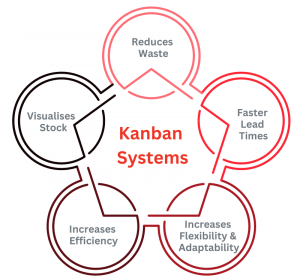

Benefits of Implementing Kanban Systems:

- Optimised Inventory: Kanban systems help you maintain optimal inventory levels by only replenishing items as needed, reducing excess stock and the associated costs.

- Waste Reduction: By streamlining inventory processes and minimising overproduction, Kanban systems help eliminate waste and improve resource utilisation.

- Enhanced Efficiency: Kanban systems enable better coordination between different departments, resulting in smoother production flows, shorter lead times, and increased productivity.

- Visual Management: With Kanban, inventory status is easily visible, allowing teams to quickly identify issues, locate items, and make informed decisions.

- Flexibility and Adaptability: Kanban systems are highly flexible and can be adapted to suit various industries, processes, and workflows, making them suitable for diverse manufacturing environments.

The Role of TwinBin Systems:

Our TwinBin systems leverage the principles of Kanban to address the inventory management challenges faced by world-class organisations.

With their innovative two-bin design and visual management features, TwinBin systems enable you to implement a robust Kanban system tailored to your specific needs. By integrating TwinBin systems into your operations, you can improve inventory visibility, enhance stock control, and streamline your workflow, ultimately driving greater efficiency and profitability.

Conclusion

In conclusion, Kanban systems represent a powerful tool for revolutionising inventory management and driving operational excellence in today’s competitive landscape. By implementing Kanban principles and leveraging innovative solutions like TwinBin systems, you can optimise your inventory, reduce waste, and enhance efficiency, paving the way for sustainable growth and success.

Are you ready to transform your workflow with Kanban systems? Contact us today to learn more about how TwinBin systems can help you achieve your inventory management goals.