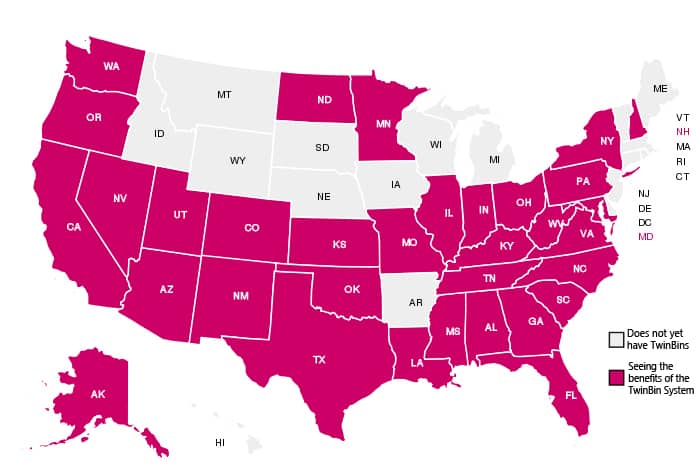

Hurst Green Plastics Ltd have proudly sold their range of innovative storage solutions including the TwinBin System to 32 states in the USA.

The TwinBin System has just been delivered to Anchorage, Alaska which added the state to the growing list of states already seeing the many benefit of the system. The TwinBin System has many benefits which include:

- Reduces and can prevent stock outs

- First in First out (FiFO stock rotation)

- Provides traceability of parts

- Reduces stock held

The TwinBin System works by storing reserve stock above active stock in a Two Bin System. Once the active stock has been depleted the user simply pulls the slider to release the reserve stock into the active stock chamber. Once the slider is pulled a red flag pops up informing the manager of the bins that more stock is required. Once more stock is on the way the manager simply changes the flag to yellow. Once the next batch is available its placed into the reserve chamber and the flag is set back to green and the cycle continues.

The TwinBin System saves companies time & money with their inventory control of fasteners, fixings and small parts. It can also assist Fastener Distribution companies with their VMI programmes. The TwinBin System has been sold to over 57 Countries across the world with new markets becoming available all the time.

The TwinBin System isn’t just for Aerospace.

The system has been successfully installed in Rail & Engineering facilities across the world and even Hospitals and Dental facilities have enjoyed the benefits of the system and seen the cost saving opportunity and return on investment.