What is Kanban?

Kanban is a methodology in lean manufacturing which manages and improves workload within production. Originally developed in Japanese automotive factories, the word ‘Kanban’ can be roughly translated to mean ‘Visual Signal’ and is used as a Just-In-Time (JIT) method of inventory control. In order to maintain inventory levels, a visual signal is created to trigger stock movements and therefore deliver more product as required by the operator. The signal may be visible to suppliers and buyers throughout the replenishment cycle.

The aim of a Kanban system is to eliminate excess inventory throughout the production cycle and align inventory levels with actual consumption, whilst highlighting any inefficiencies within the supply chain. In order to obtain accurate inventory levels, it is essential that plenty of planning has taken place in order to gather information to ensure that the Kanban system works efficiently; this information can include, but is not limited to, the lead time of the parts, the quantity consumed in a time-specific basis (daily/weekly/monthly) as well as further information, such as product use-by dates (if relevant) and any Minimum Order Quantities (MOQs) of the product. It is also important to be aware of any changes within the manufacturing calendar that could affect the consumption rate, such as an increase or decrease in production in the given time.

How can you implement Kanban?

The most basic and simple implementation of a Kanban system can be done through a two-bin system.

Did you know that we manufacture a range of Kanban storage systems, including a two-bin system?

You can see our innovative two-bin Kanban system, the TwinBin System here.

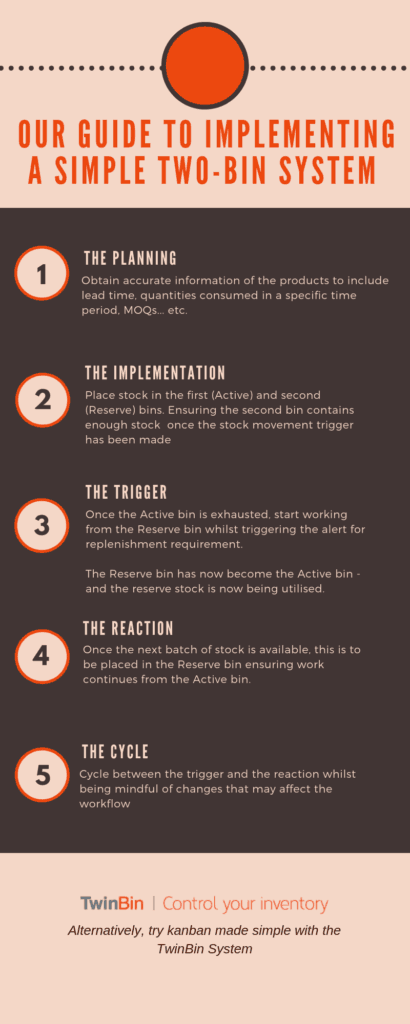

Please see below our guide to implementing a simple two-bin system:

- Firstly, gathering information and planning is crucial for all items wishing to be stored in a Kanban system. Important information such as quantities used, the lead time and product MOQs need to be understood and analysed for the two-bin system to work. If this is not completed correctly then there may be too much, or too little stock available and the system will fail.

- Once enough data has been gathered and researched, it is time to implement the two-bin system. The stock needs to be placed in the two-bin system, ensuring the second bin contains enough stock for production to continue once the stock replenishment trigger has been activated – this information should be available from all the data gathered during the planning stage.

- There needs to be a trigger in the Kanban system to display a visual signal once the replenishment request has been activated. This can be a simple signal such as a Kanban card or something complex as an RFID Alert (or by using our TwinBin System which does this for you!).

- Ensure that production begins with the first bin, which we call the ‘Active Bin’. Once the stock is exhausted, production moves on to the second bin, which we call the ‘Reserve Bin’. Once the reserve bin comes into play, it then changes to become the active bin. A visual signal then needs to be triggered in order for stock movement requirement to be activated.

- Once more stock has become available, this needs to be placed into the (now empty) reserve bin and placed back into production to be utilised once the active bin is exhausted.

- Once the reserve bin has been replenished, this then resets the cycle whilst production continues.

- It is important to note that regularly returning to the planning stage is crucial to ensure to the efficient running of the Kanban system, regularly checking for changes in lead times, MOQs and changes in production that can influence the Kanban system.

See how we’ve made Kanban simple with our TwinBin system

Request your free sample here and you can start seeing the benefits of a two-bin Kanban system.